The use of 3D printing in motor racing has become increasingly common. The ability to rapidly produce, customize and select the most appropriate materials for each application has led many automakers to adopt this technology. In Formula 1, for example, the collaboration between Visa Cash App RB and ROBOZE illustrates this trend, as do initiatives by Ferrari and McLaren Racing, among others.

A recent application of 3D printing on the racetrack is the development of parts for Lamborghini’s new SC63 hypercar. Notably, during the 24 Hours of Le Mans, Lamborghini urgently called on local company EProjets Lab to 3D print parts otherwise unavailable, but essential for the race.

Lamborghini and Iron Lynx Join Forces to Take Endurance Racing to the Next Level

Lamborghini’s incredible SC63 hypercar was revealed at the Goodwood Festival of Speed 2023, an annual motorsport event held at the Goodwood circuit in England. The car subsequently took part in the 2024 World Endurance Championship (FIA WEC) and the IMSA WeatherTech SportsCar Championship, marking a significant milestone for Lamborghini. The SC63 is a hybrid prototype powered by a 3.8-liter twin-turbo V8 engine, representing the most advanced racing car ever built by the Italian automaker.

For the 2024 races, Lamborghini has established a strategic partnership with Iron Lynx to optimize the car’s performance and attract world-class drivers from Formula 1 and endurance racing, such as Mirko Bortolotti, Andrea Caldarelli, Daniil Kvyat and Romain Grosjean.

3D Printing for the SC63 at the 24 Hours of Le Mans

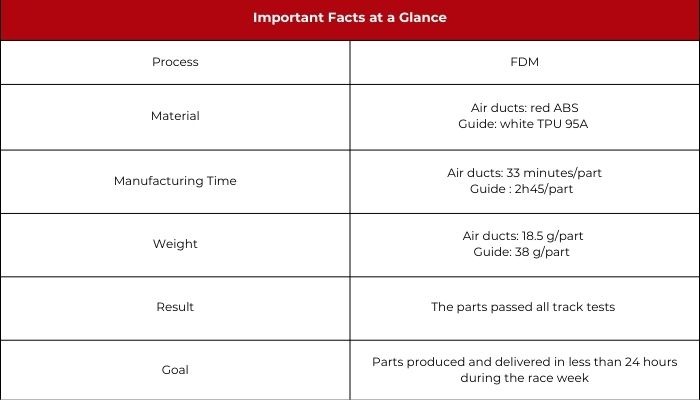

During the fourth round of the FIA WEC championship, the 24 Heures du Mans, Lamborghini and Iron Lynx commissioned EProjets Lab to urgently produce a series of parts using 3D printing. These parts included two air ducts for the cockpit ventilation system, to ensure optimum thermal management for the drivers, and two guides for the vehicle’s pneumatic lifting system. These guides were essential to facilitate pit stops, ensuring correct and reliable operation of the insertion and removal system.

The air ducts were manufactured using the FDM process from red ABS, which ensured the part’s strength and lightness. For the guides, on the other hand, the challenge was to manufacture them in a short space of time and using strong, durable materials, as these parts had already experienced resistance problems in the past. Indeed, these parts are ejected once the pit stop is over, and break easily as they fall onto the asphalt. It was therefore important to choose a material that was flexible and strong enough not to break after repeated falls.

The 3D printing material TPU 95A proved to be the optimum choice, due to its flexibility and impact resistance, ensuring reliable, long-lasting performance even under extreme conditions. The FDM process was again selected for this application.

EProjets Lab delivered the 3D printed parts in less than 24 hours, as confirmed by the 3D printing service. This rapid turnaround was made possible by the flexibility and speed of additive manufacturing. “We received the parts very quickly, at a competitive cost and with exceptional quality. We’re very impressed,” says John McGill, Engineering Coordinator at Iron Lynx Lamborghini.

3D printing was thus able to meet Lamborghini’s and Iron Lynx’s specific requirements in terms of production time, precision and customization. After the 2024 Le Mans 24 Hours, the parts 3D printed by EProjets Lab underwent further testing, confirming their durability. Lamborghini SC63s also used these parts at the IMSA 6 Hours of Watkins Glen, performing on the Watkins Glen International Circuit throughout the race. For more information, visit the website HERE.

Cover Photo Credits: Lamborghini